How Does a Push Button Switch Differ from a Regular Switch

In the realm of electrical switches, both push button switches and regular switches play crucial roles, yet they have distinct characteristics that set them apart. Understanding these differences can help in making the right choice for various applications.

Structural Disparities

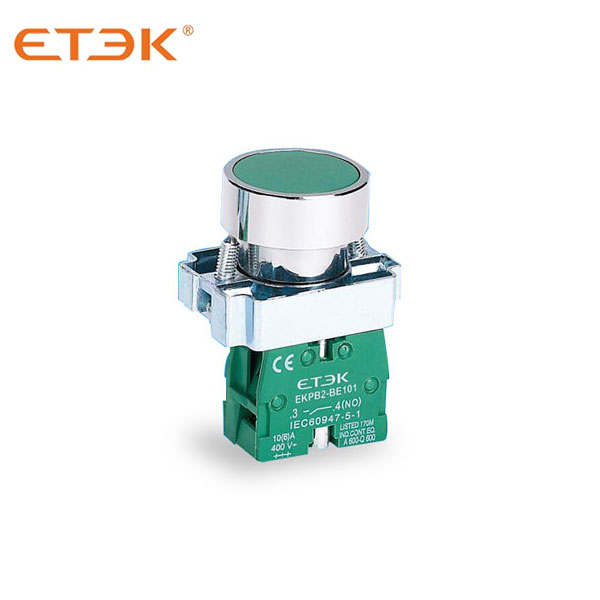

Regular switches often feature a toggle - like structure. This typically consists of a lever that can be flipped up or down. The lever is directly connected to the internal contact mechanism. For example, in a common household light switch, the lever's movement changes the position of the contacts, either closing or opening the circuit. On the other hand, a push button switch has a more compact and vertically - oriented design. It has a button actuator that is pressed down into the housing. Inside the housing, there are components like springs and contacts that are activated by the vertical force of the button press. This structural difference gives each type of switch its unique operational feel and appearance.

Operational Mechanics

The operation of a regular switch is based on a continuous - state change. Once the toggle is moved to the on or off position, it remains in that state until it is manually moved again. This provides a stable connection or disconnection of the circuit. In contrast, push button switches have different operation modes. Momentary push button switches are designed such that the circuit is only open or closed while the button is being pressed. As soon as the button is released, the switch returns to its original state. Maintained push button switches, though, stay in the on or off position after the button is pressed and require another press to change the state. This difference in operation makes regular switches suitable for applications where a continuous state is needed, like lighting fixtures, while push button switches are more versatile for applications that require either momentary or controlled - state changes, such as starting a motor for a short period or toggling a device's settings.

Application - Specific Use Cases

Regular switches are commonly found in residential and commercial lighting systems. They are also used in basic electrical appliances where a simple on - off function is required, like a table lamp or a ceiling fan speed controller. In industrial settings, they may be used for large - scale equipment that needs to be in a continuous operation state. Push button switches, on the other hand, have a wider range of applications. In industrial machinery, they are used for emergency stop functions, as the momentary action allows for quick circuit interruption. In automotive interiors, push button switches are used for various functions such as controlling the horn, which requires a momentary contact, or for functions like starting the engine in modern cars with push - start systems. In electronic devices, they are used for user - input functions, where the compact size and easy - to - press nature of the button are advantageous.

Durability and Wear Considerations

Regular switches, with their relatively simple toggle mechanism, can be quite durable in applications where they are not frequently operated. However, over time, the repeated flipping of the lever can cause wear and tear on the contact points and the moving parts. Push button switches, especially those with momentary operation, are designed to handle a large number of presses. The internal spring - loaded mechanisms are engineered to withstand the constant pressure and release cycles. But in maintained push button switches, the latching mechanism may be more prone to wear if not properly designed, as it has to hold the switch in a particular state over an extended period.

In conclusion, while both push button switches and regular switches are essential for controlling electrical circuits, their differences in structure, operation, application, and durability make them suitable for different scenarios. By understanding these differences, engineers, electricians, and consumers can make more informed decisions when choosing the right switch for their specific needs. With expertise in these nuances, a diverse range of customized solutions can be offered, whether you need a specific type of switch for a unique project or a large - scale production run. Reach out, and let's explore how your switch - related requirements can be met.

.jpg)