What is the difference between a magnetic contactor and a circuit breaker?

Introduction

In electrical systems, both magnetic contactors and circuit breakers play vital but distinct roles. While they may appear similar to the untrained eye, these components serve fundamentally different purposes in power distribution and control circuits. Understanding the differences between magnetic contactors and circuit breakers is essential for proper electrical system design, installation, and maintenance.

I.What is a Magnetic Contactor?

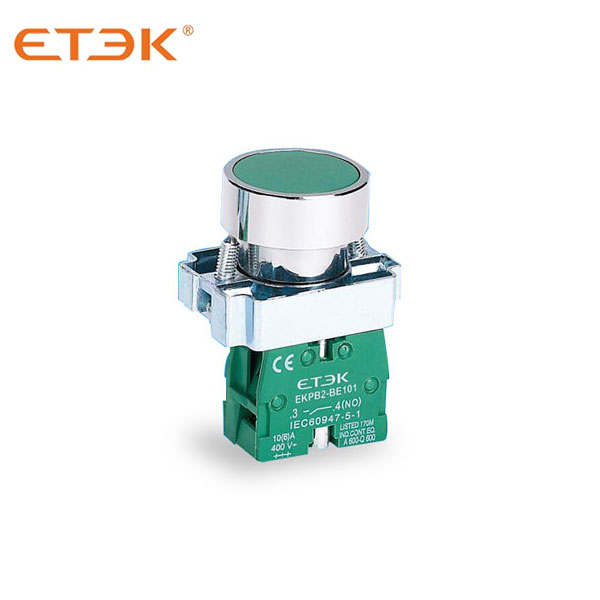

A magnetic contactor is an electrically controlled switch used for switching power circuits, similar to a relay but capable of handling higher current ratings. It operates using an electromagnetic coil that creates a magnetic field when energized, pulling contacts together to complete the circuit.

Key Features of Magnetic Contactors:

Electromagnetic operation: Uses a coil to mechanically close contacts

Remote control capability: Can be operated from a distance via control signals

High switching capacity: Designed for frequent operations (thousands to millions of cycles)

No overload protection: Doesn't provide protection against overcurrent conditions

Modular design: Often includes auxiliary contacts for control circuits

II.What is a Circuit Breaker?

A circuit breaker is an automatic electrical switch designed to protect an electrical circuit from damage caused by overload or short circuit. Its basic function is to interrupt current flow after protective relays detect a fault.

Key Features of Circuit Breakers:

Protective device: Safeguards circuits against overcurrent and short circuits

Trip mechanism: Uses thermal, magnetic, or thermal-magnetic mechanisms to open the circuit

Manual operation: Can be manually switched on/off like a switch

One-time operation: Not designed for frequent switching (though can be reset after tripping)

Current-limiting: Some types can interrupt extremely high fault currents

III.Key Differences Between Magnetic Contactors and Circuit Breaker

| Feature | Magnetic Contactor | Circuit Breake |

| Primary Function | Switching device for normal operations | Protective device for fault conditions |

| Operation Frequency | Designed for frequent operations (thousands of cycles) | Limited operations (not for regular switching) |

| Overcurrent Protection | No inherent protection | Provides overcurrent and short-circuit protection |

| Control Method | Electromagnetic (requires continuous power to maintain state) | Manual or automatic trip mechanism |

| Normal State | Normally open or closed contacts (depending on design) | Normally closed during operation |

| Usage | Motor control, lighting control, power distribution | Circuit protection in distribution panels |

| Reset Operation | Automatically returns to normal state when de-energized | Requires manual reset after tripping |

IV.When to Use Each Device

Use a Magnetic Contactor When:

You need to remotely control a circuit

Frequent switching operations are required (like motor start/stop)

You need to control high-power loads with low-power control signals

Implementing automation sequences in industrial controls

Use a Circuit Breaker When:

You need to protect a circuit from overcurrent conditions

You require short-circuit protection

You need a manual disconnect means for maintenance

Permanent circuit protection is needed at distribution points

V.Complementary Roles in Electrical Systems

In many applications, magnetic contactors and circuit breakers work together. A typical motor control circuit might include:

1. Circuit breaker: Provides overcurrent and short-circuit protection

2. Magnetic contactor: Allows remote start/stop control of the motor

3. Overload relay: Provides motor-specific overload protection

This combination leverages the strengths of each device - the circuit breaker protects against catastrophic faults, while the contactor enables convenient control.

VI.ETEK Low voltage electrical appliance solution expert

ETEK is a professional manufacturing company dedicated to the research and development, production and sales of low-voltage electrical appliances, we have always focused on the field of low-voltage electrical appliances, with advanced production management systems and perfect production process flows. Our product line covers power safety products for household, commercial, industrial and similar facilities, including circuit breakers, fuses, residual current protection devices (RCD), surge protectors (SPD), arc fault circuit breakers (AFCI) and other electrical protection devices, which can meet the needs of different scenarios.

We are well aware that different products will be different for different scenarios. Etek will select the right product for you according to your environment to protect your property and life safety. At present, our products are distributed in more than 60 countries around the world, with six independent production lines. With diversified products and perfect quality, we are well received by customers. If you still don't know how to choose the right product, our professionals will patiently answer your questions and look forward to your message.

Conclusion

While magnetic contactors and circuit breakers may share some superficial similarities, they serve fundamentally different purposes in electrical systems. Contactors excel at frequent, controlled switching of circuits, while breakers specialize in circuit protection. Understanding these differences ensures proper selection and application of these critical components in any electrical installation.

For optimal system design and safety, engineers often combine both devices to achieve both reliable control and complete circuit protection. Always consult electrical codes and standards, and consider working with qualified professionals when designing or modifying electrical systems.

.jpg)