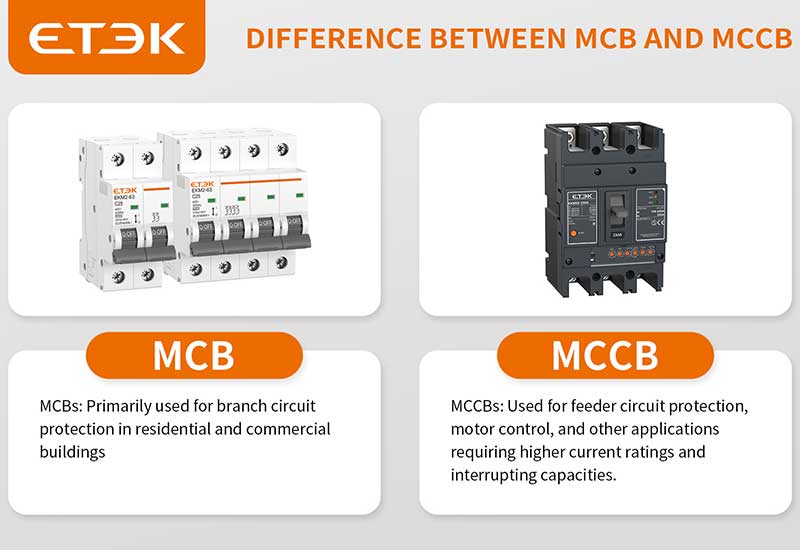

Difference between MCB and MCCB in Electrical Systems

Introduction:

In the field of electrical safety, Miniature Circuit Breakers (MCB) and Molded Case Circuit Breakers (MCCB) are crucial for protecting electrical circuits from overload or short circuits. Although they appear similar, they are designed for different applications and have distinct features tailored to specific requirements in electrical systems.

What is MCB (Miniature Circuit Breaker)?

An MCB is a type of electrical switch designed to automatically turn off the electrical circuit during abnormal conditions such as overload and short circuits within domestic or commercial installations. It provides protection for smaller loads and is typically used in low current circuits.

Key Features of MCB:

- Compact size

- Designed for low current applications (up to 100 Amperes)

- Offers protection against overload and short circuit

- Quick response to fault conditions

- Easy to reset without the need for replacement

- Suitable for residential and light commercial applications

What is MCCB (Molded Case Circuit Breaker)?

MCCB stands for Molded Case Circuit Breaker, which is a type of electrical protection device that can handle higher current ratings and can provide adjustable trip settings. MCCBs are used in industrial environments as well as commercial applications where higher current load capacity is required.

Key Features of MCCB:

- Larger in size than MCBs

- Higher current ratings (up to 2500 Amperes or more)

- Adjustable trip settings for precise protection

- Provides protection against overload, short circuit, and ground fault

- Suitable for industrial applications and high-power equipment

- Can be used as a main breaker for an entire system

Differences between MCB and MCCB:

1. Current Rating: MCBs are typically used for circuits with lower current ratings, usually not exceeding 100 Amperes. In contrast, MCCBs can handle much higher currents, often extending up to 2500 Amperes or more.

2. Interrupting Capacity: MCCBs have a higher interrupting capacity, meaning they can handle larger short-circuit currents without damage, compared to MCBs.

3. Size and Construction: MCBs are smaller and more compact than MCCBs, making them suitable for space-constrained applications. MCCBs, being larger, are commonly used in industrial settings where space is less of a constraint.

4. Trip Characteristics: While MCBs typically have fixed trip characteristics, MCCBs offer adjustable trip settings that allow for greater flexibility in protecting against electrical faults.

5. Application: MCBs are commonly used in residential and light commercial settings, whereas MCCBs find their use in commercial and industrial environments that require handling of higher power and more complex systems.

6. Cost: Due to their higher capacity and adjustable features, MCCBs are more expensive than MCBs.

Here's a table summarizing the key differences:

|

Feature |

MCB |

MCCB |

|

Current Rating |

1A-100A |

10A-2000A |

|

Interrupting Capacity |

6kA-10kA |

10kA-100kA |

|

Application |

Residential, small commercial |

Industrial, large commercial |

|

Size |

Compact |

Larger |

|

Cost |

Less expensive |

More expensive |

|

Tripping Mechanism |

Thermal-magnetic |

Thermal-magnetic, electronic |

|

Adjustable Settings |

Fixed |

Adjustable |

Conclusion:

Choosing between an MCB and an MCCB depends on the specific requirements of the electrical system in question. For lower current applications such as home wiring, an MCB is often sufficient. However, for larger commercial or industrial setups where the load demand is greater, an MCCB would be the more appropriate choice due to its higher current handling capacity and adjustable trip settings.

When selecting products, it is important to source them from reputable manufacturers such as ETEK Electric to ensure quality and reliability. Visit https://www.etek-china.com to explore the full range of products for comprehensive solutions.

.jpg)